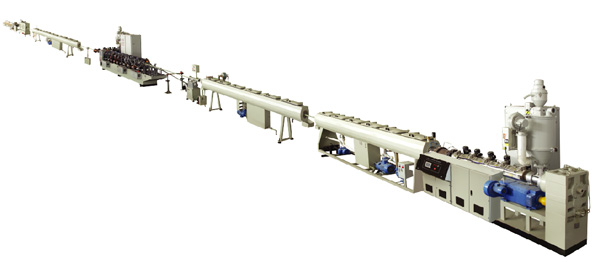

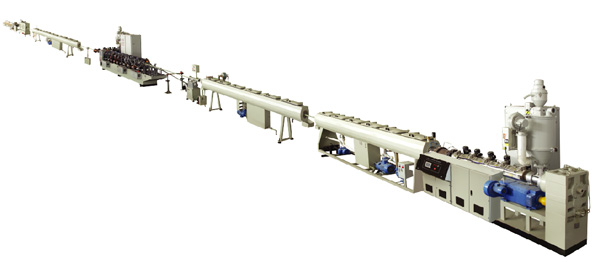

擠出機:采用品牌調速系統,屏障型兩極混煉PP-R專用螺桿,開槽機筒。

定徑部分:采用真空負壓定型及循環水冷卻,不銹鋼板制作。

牽引部分:采用氣動夾緊,品牌變頻調速,可實現管材的穩定牽引。

成形部分:具有完美的成形和復合工藝,確保管材合理結合在一起。

自動化控制:采用日本三菱恍C可編程計算機控制,可實現擠出量、牽引、復合成形、切割的程序

控制,確保整條生產線(PLD)閉環。

Extruder: It has adopted the famous brand

speed-regulating systems, shielding double-pole mixed

PP-R specialized screw and the cylinder which has channels in it.

Diameter setting part: It has adopted vacuum negative pressure

setting and recycled water cooling and it is made of stainless steel.

Drawing part: It has adopted pneumatic gripping and the famous brand frequency

control systems which enable the stable drawing of the pipes.

Molding part: It has adopted perfect molding and compounding technology which guarantee the

perfect combination of pipes.

Automatic control: By using PLC programmable computer control system from Mitsubishi of Japan, it can

make the extruding quantity, drawing, compounding and molding, cutting all controlled by programs, so that the whole

production line is a closed circle.

|